Powder composite cores

We use specifically developed hydraulic powder presses and precision tools for the manufacture of our high grade pot-type, ring and bespoke cores. Using high pressure and temperatures and our powder composite material HaKRon® we produce stable moulded cores which are then sintered. Naturally, due to continuously changing demands, our base material as well as our build options are constantly being improved by our design engineers.

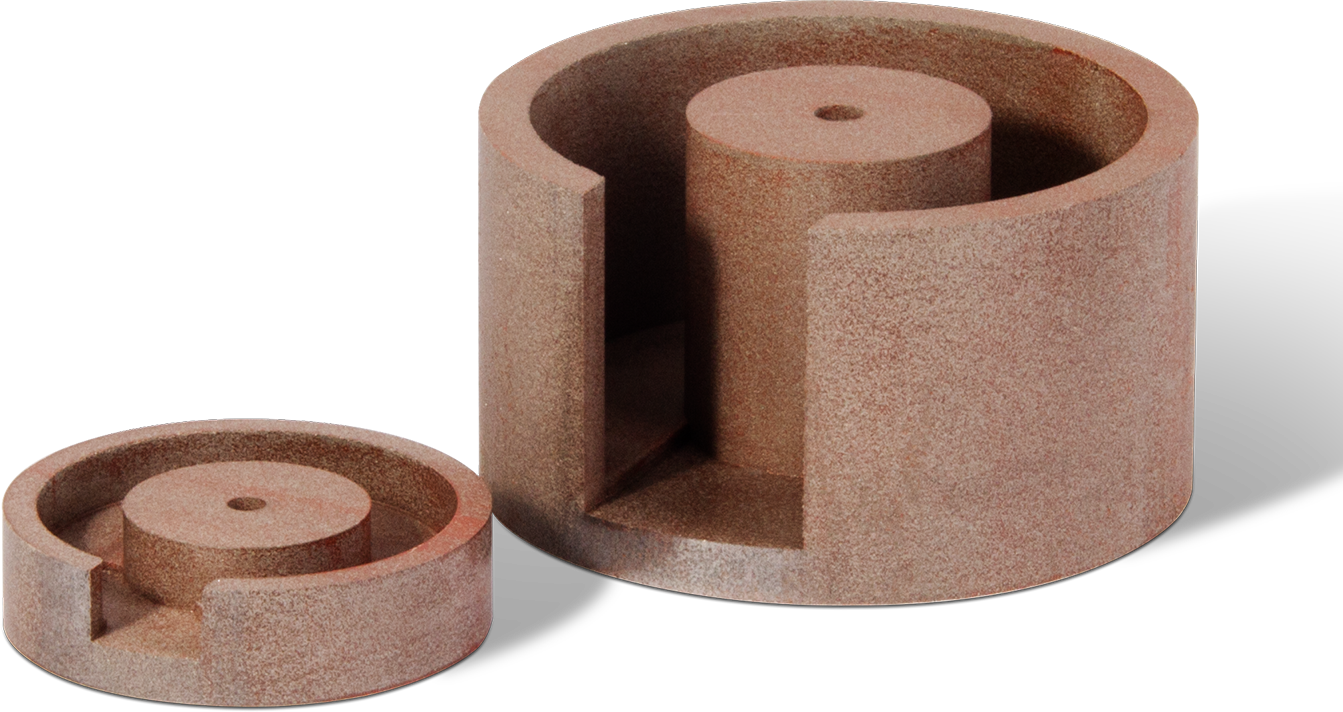

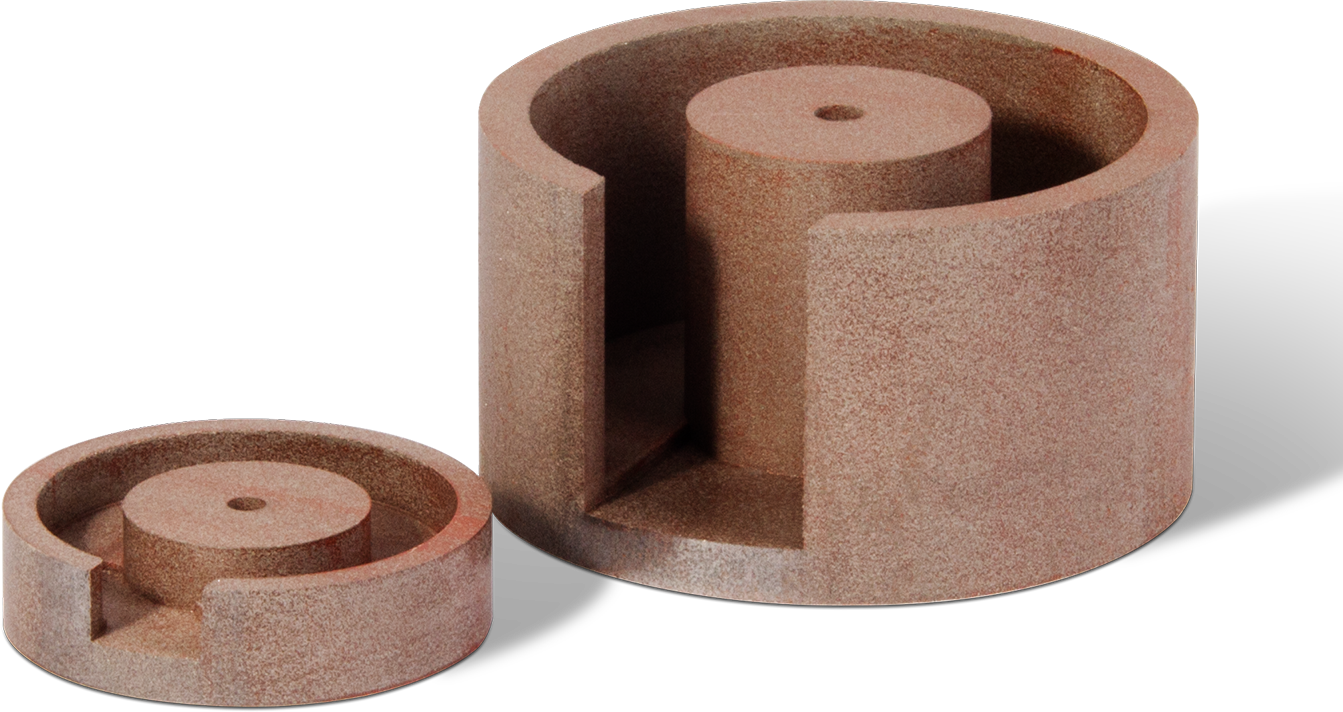

Pot-type cores

Our pot type cores are manufactured from our magnetically soft composite HaKRon® - in standard diameters or on request with additional air gap. The height can be individually adjusted and configured according to you requirements. For attachment purposes our pot-type cores come with a central hole with according diameter. They are available in pressed finish or with corrosion protection.

Technical Data:

- high saturation induction

- high modulation capability through finely dispersed air gaps

- minimum eddy current losses

- suitable even at high switching frequencies

Ring cores

Our ring cores are manufactured from our magnetically soft composite HaKRon® - in standard diameters. The height can be individually adjusted and you have a choice between pressed finish and corrosion protection.

Technical Data:

- high saturation induction

- high modulation capability through finely dispersed air gaps

- minimum eddy current losses

- suitable even at high switching frequencies

Customer specific cores

Naturally, we can design and supply customized cores and forms. With HaKRon®, our innovation in composites, this can be extended to units with a complex geometry for electro technical use. Please contact us for a bespoke offer.